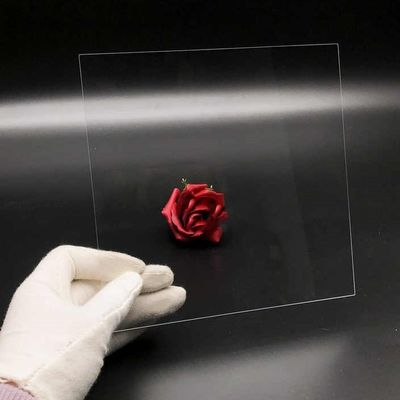

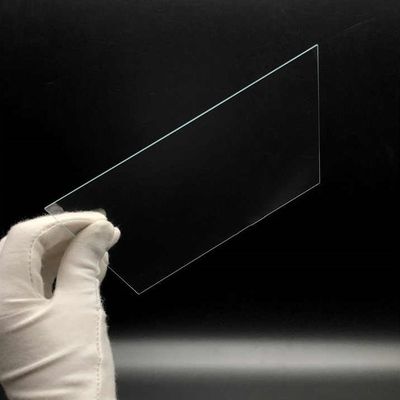

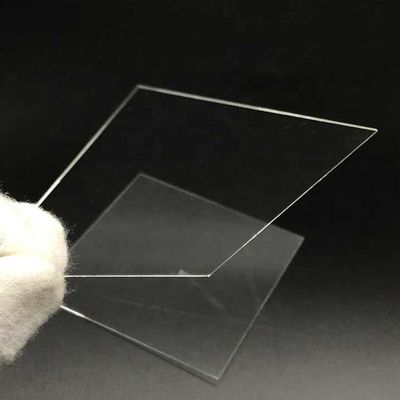

Our factory has invested 2.5 billion RMB, covering an area of 300 acres. Our main product line is the "silk" series original glass sheet for high-end electronic display cover glass and protective glass, which is an environmentally friendly aluminosilicate ultra-thin high-strength glass. It features excellent flexibility, scratch resistance, bending strength and impact resistance.

We use the world's most advanced process technology with an annual production capacity of 20 million square meters and compatible with products ranging from 10.5 to 5 generations of glass.

There are 18 process during the whole production.

We adopt the Float Glass Process to manufacture the ultra thin ultra clear glass original sheet.

Float glass is made by heating raw materials—silica sand, limestone, soda ash, and magnesium in a furnace. When melted, it’s then spread out over a sizable bed of molten tin. As it moves along rollers in the annealing oven during a controlled cooling process, this mixture slowly solidifies over the molten tin. From this point, a single, continuous smooth ribbon of glass emerges. The production diagram is as below picture showed:

1. Batching

Raw materials are inspected and precise weighed, mixed and moved by conveyor into the furnace. Water is added to help mix the batch and minimize airborne dust.

2. Melting

The raw materials are fed into furnace with full melting at temperatures reaching 2900 degree F.

3. Refining

Refinement: The molten glass is homogenized and bubbles removed.

Temperature Control: Molten glass is cooled to approximately 2000 degree F where is ready for the tin float bath.

4. Forming

Glass takes its shape as it flows over a smooth bath of molten tin, the glass leaves the tin bath at around 1000 degrees F. The Gear wheels stretch or push the glass to obtain the required thickness and width.

Our own "Similar to Thinner" Technology can strictly control the thickness of glass difference within 0.01mm, which is far exceeding the domestic average.

5. Annealing

The glass ribbon is drawn off the tin bath and cooled gradually in a cooling tunnel to create a flat, parallel surface. After the molten tin bath, the rigid glass ribbon goes through the cooling tunnel or lehr. This lowers the glass temperature from around 1000 degree F to close to room temperature.

6. Inspection and Cutting

The continuous glass ribbon is electronically inspected by the world's most advanced Isla Testing Eequipment to inspect the quality, which can automatically inspect every single glass sheet to ensure the quality.

And also our colleagues of quality control department will inspect during the process.

The glass ribbon is automatically cut into sheets with the appropriate size by the most advanced Green Cutting System.

7. Stacking and Packing

The glass sheets are lifted by suction-cup stackers or by robots and placed on pallet to be packed by packers and then be stored in the warehouse or shipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!